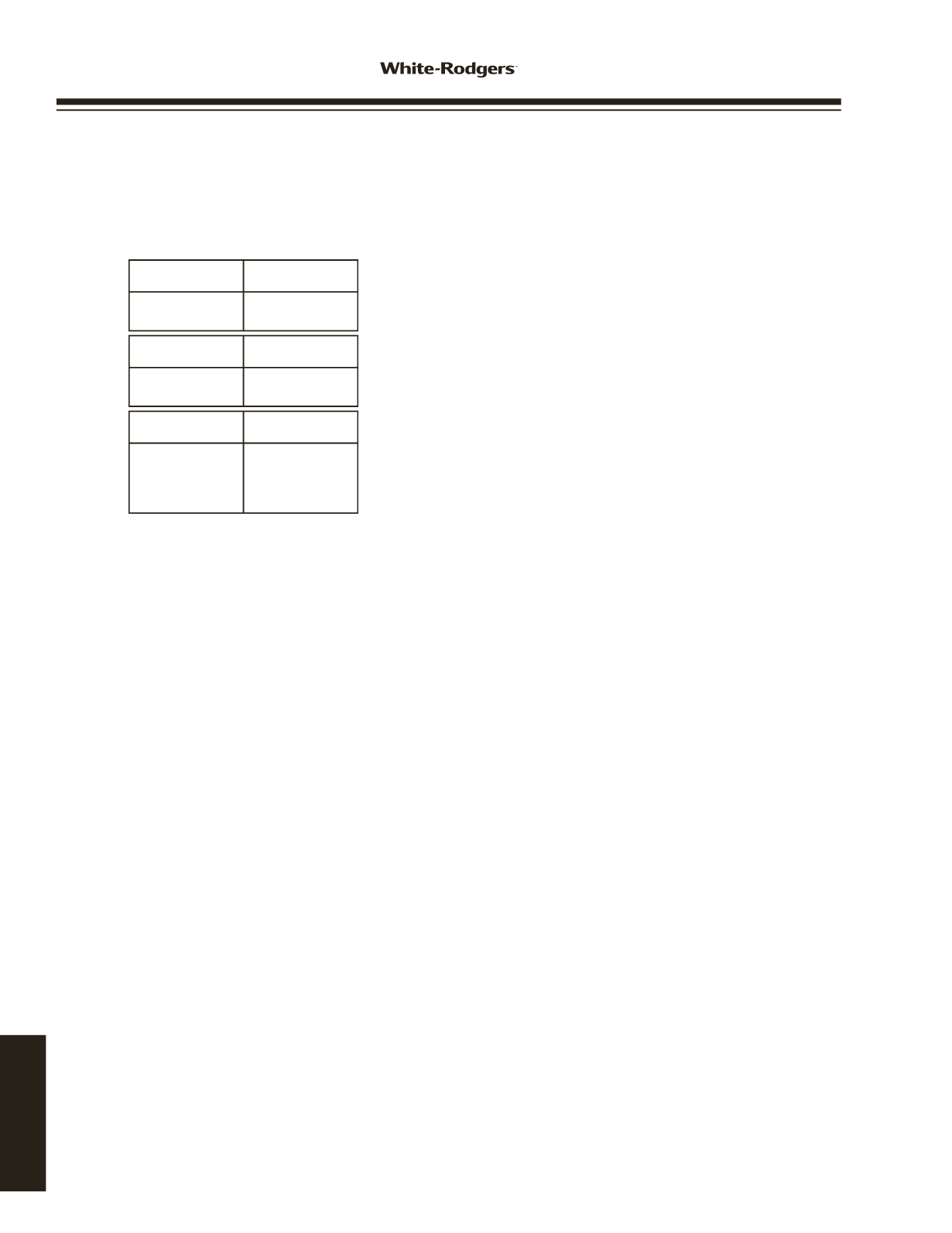

OPTION SWITCHES

The option switches on the 50A65-843 control are used to

determine the length of the cool delay-to-fan-off, heat delay-

to-fan-on and heat delay-to-fan-off periods. The following

table shows the time periods that will result from the various

switch positions.

HEAT MODE

In a typical system, a call for heat is initiated by closing the

thermostat contacts. This starts the 50A65 control’s heating

sequence. The inducer blower and optional humidifier are

energized and the 768A silicon nitride ignitor is powered

within one second.

This control has an adaptive algorithm that reduces the ignitor

temperature to slightly greater than the minimum temperature

required to ignite gas in each particular application. The con-

trol measures the line voltage and determines an initial ignitor

temperature setting based on the measurement. After each

successful ignition, the control lowers the ignitor temperature

slightly for the next ignition attempt. The control continues to

lower the ignitor temperature until ignition does not occur, and

the control goes into retry mode. For the second attempt to

ignite gas within the same call for heat, the control increases

the ignitor temperature to the value it was on the third previ-

ous successful ignition. After ignition is successful, the control

sets the ignition temperature at this value for the next 255

calls for heat, after which the control repeats the adaptive

algorithm. The control is constantly making adjustments to

the ignitor temperature to compensate for changes in the line

voltage.

The 80 VAC Silicon Nitride ignitor manufactured by

White-Rodgers must be used.

These ignitors are specially

designed to operate with the 50A65’s adaptive ignition routine

to ensure the most efficient ignitor temperature.

COOL MODE

In a typical system, a call for cool is initiated by closing the

thermostat contacts. This energizes the 50A65 control and

the compressor. The cool delay-to-fan-on period begins. After

the delay period ends, the optional electronic air cleaner is

energized, and the circulator fan is energized at cool speed.

After the thermostat is satisfied, the compressor is de-

energized and the cool mode delay-to-fan-off period begins.

After the delay-to-fan-off period ends, the circulator fan and

electronic air cleaner (optional) are de-energized.

MANUAL FAN ON MODE

If the thermostat fan switch is moved to the ON position, the

circulator fan (cool speed) and optional electronic air cleaner

are energized. When the fan switch is returned to the AUTO

position, the circulator fan and electronic air cleaner (optional)

are de-energized.

SYSTEM LOCKOUT FEATURES

When system lockout occurs, the gas valve is de-energized,

the circulator blower is energized at heat speed, and, if flame

is sensed, the inducer blower is energized. The diagnostic

indicator light will flash or glow continuously to indicate

system status. (

System lockout will never override the

precautionary features

.)

To reset the control after system lockout,

do one of the

following:

1. Interrupt the call for heat or cool at the thermostat for at

least one second but less than 20 seconds (if flame is

sensed with the gas valve de-energized, interrupting the

call for heat at the thermostat will

not

reset the control).

2. Interrupt the 24 VAC power at the control for at least one

second. You may also need to reset the flame rollout

sensor switch.

3. After one hour in lockout, the control will automatically

reset itself.

DIAGNOSTIC FEATURES

The 50A65-843 control continuously monitors its own

operation and the operation of the system. If a failure occurs,

the LED will indicate a failure code as shown below.

If the

failure is internal to the control, the light will stay on

continuously. In this case, the entire control should be

replaced, as the control is not field-repairable

.

If the sensed failure is in the system (external to the control),

the LED will flash in the following flash-pause sequences to

indicate failure status (each flash will last approximately 0.25

seconds, and each pause will last approximately 2 seconds).

1 flash, then pause

System lockout

2 flashes, then pause Pressure switch stuck closed

3 flashes, then pause Pressure switch stuck open

4 flashes, then pause Open limit switch

5 flashes, then pause Open rollout switch

6 flashes, then pause 115 Volt AC power reversed /

Improper ground

7 flashes, then pause Low flame sense signal

8 flashes, then pause Check ignitor

Continuous flashing

Flame has been sensed when

(no pause)

no flame should be present (no

call for heat)

The LED will also flash once at power-up.

Trane application

- Jumper wire 151-2906 (provided with

control) must be installed on the furnace from R01 to R02 of

the 12-pin connector.

HEAT delay-

to-fan-off:

Set switch

#3 #4

60 sec.

90 sec.

120 sec.

180 sec.*

On On

Off On

On Off

Off Off

COOL delay-

to-fan-off:

Set switch

#1

45 sec.*

90 sec.

On

Off

HEAT delay-

to-fan-on:

Set switch

#2

30 sec.*

45 sec.

On

Off

OPTION SWITCH POSITIONS

* Factory setting

WIRING AND

CONFIGURATION

50A65-843

www.white-rodgers.com186

TECHNICAL HELP