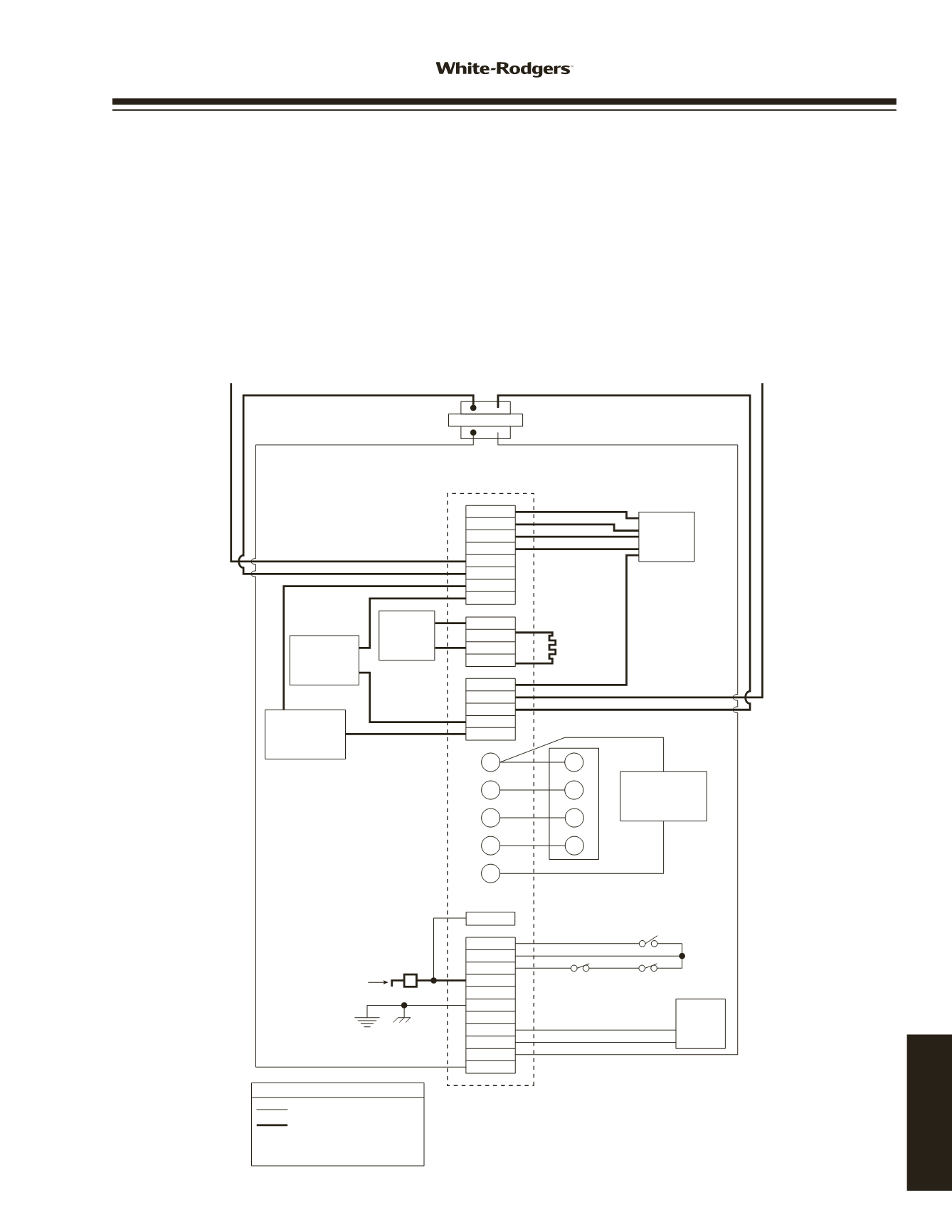

50A65-843

WIRING AND

CONFIGURATION

TH

TR

MV

MV

GND

FP

HLO

HLI

PS

C

R

G

W

Y

EAC N

E33

HUM N

XFMR N

LINE N

CIR N

IGN N

IND N

IGN

IND

HUM

EAC

XFMR

LINE

PARK

PARK

HEAT

COOL

IGNITOR

Y

W

G

R

THERMOSTAT

GAS

VALVE

HIGH LIMIT

(N. C.)

AUX. HIGH

LIMIT (N. C.)

PRESSURE SWITCH (N. O.)

FLAME

SENSOR

PROBE

COMPRESSOR

CONTACTOR

ELECTRONIC

AIR CLEANER

HUMIDIFIER

INDUCER

CIRCU-

LATOR

BLOWER

50A65-843

24 VAC

120 VAC

24 VAC CLASS II

TRANSFORMER

HOT

(LINE)

NEUTRAL

(LINE)

TH

TR

Low Voltage (24 VAC)

Line Voltage (120 VAC)

LEGEND

N. C. = Normally closed switch

N. O. = Normally open switch

TYPICAL SYSTEM WIRING DIAGRAM

The 50A65-843 is an automatic gas interrupted ignition

control that employs a microprocessor to continually monitor,

analyze, and control the proper operation of the gas burner,

inducer, and fan.

Signals interpreted during continual surveillance of the ther-

mostat and flame sensing element initiate automatic ignition

of the burner, sensing of the flame, and system shut-off dur-

ing normal operation.

These controls incorporate system fault analysis for quick gas

flow shut-off, coupled with automatic ignition retry upon sens-

ing a fault correction.

Flame Current Requirements:

Minimum current to insure flame detection.............1 µa DC

➀

Maximum current for non-detection.....................0.1 µa DC

➀

Maximum allowable leakage resistance............. 100 M ohms

Flame establishing time......................0.8 seconds maximum

Flame failure response time................2.0 seconds maximum

➀

Measured with a DC microammeter in the flame probe lead

50A65-843

www.white-rodgers.com185

TECHNICAL HELP