OPERATION

50M56U-843

DIAGNOSTIC FEATURES

The 50M56U-843 control continuously monitors its own operation

and the operation of the system. If a failure occurs, the LED will

indicate a failure code as shown below.

If the failure is internal to

the control, the light will stay off. In this case, the entire control

should be replaced, as the control is not field-repairable.

If the sensed failure is in the system (external to the control), the

LED will flash in the following flash-pause sequences to indicate

failure status (each flash will last approximately 0.25 seconds, and

each pause will last approximately 2 seconds).

DIAGNOSTIC INDICATOR FLASH CODES

FLASH

1

System Lockout (Retries Exceeded)

2

Pressure Switch Stuck Closed

3

Pressure Switch Stuck Open

4

Open High Temperature Limit Switch

5

Flame Sensed with Gas Valve De-energized

6

Open Rollout Switch

7

Low Flame Sense Signal

8

Ignitor Relay Fault

Rapid Flash

Reverse Polarity

Continuous On

Normal Operation

Off

Control Failure

FAULT RECALL

The last five fault codes stored can be displayed on the diagnostic

LED.When the control is in standby mode (no call for heat or cool),

press the FAULT RECALL switch for approximately two seconds or

until the diagnostic LED turns off. Release the switch and the LED

will remain off for two seconds. Then the fault codes will display

beginning with the most recent fault first with a two second pause

between codes. After the stored fault codes have all displayed, the

LED will remain off for two seconds and then turn on to indicate

return to normal status.While displaying the stored fault codes, the

control will ignore any new call for heat, cool or fan.

FAULT CODE RESET

The stored fault codes can be erased from memory. When the

control is in standby mode (no call for heat or cool), press the FAULT

RECALL switch for five to ten seconds or until the diagnostic LED

begins to rapid flash. When the switch is released, the LED will

turn off for two seconds to indicate the codes are erased. After two

seconds the LED will turn on to indicate return to normal status. If

the switch is held pressed for over ten seconds the rapid flash will

stop and the LED will be on to indicate return to normal status.

Auto Restart

– After one (1) hour of internal or external lockout,

the control will automatically reset itself and go into an auto

restart purge for 60 seconds.

Cool Delay-To-Fan-Off

– The period of time between the loss

of a call for cool and the deactivation of the blower motor at

Cool speed.

Cool Delay-To-Fan-On

–

The period of time after a thermostat

demand for cool before energizing the circulator blower motor

at Cool speed.

Flame Failure Response Time (FFRT)

–

The period of time

between loss of the supervised main burner flame and the

action to shut off the gas supply.

Heat Delay-To-Fan-Off

– The period of time between the loss

of a call for heat and the deactivation of the blower motor at

Heat speed.

Heat Delay-To-Fan-On

– The period of time between proof of

the supervised main burner flame and the activation of the

blower motor at Heat speed.

IgniterWarm-upTime

–

The length of time allowed for the igniter

to heat up prior to the initiation of gas flow.

Ignition Activation Period (IAP)

–

The period of time between

energizing the main gas valve and deactivation of the ignition

means prior to the end of TFI.

Inter-purge

– The period of time intended to allow for the

dissipation of any unburned gas or residual products of

combustion between the failed trial for ignition and the retry

period.

Post-purge Time

– The period of time intended to allow for

the dissipation of any unburned gas or residual products of

combustion at the end of a furnace burner operating cycle.

Post-purge begins at the loss of flame sense.

Pre-purge Time

– The period of time intended to allow for the

dissipation of any unburned gas or residual products of

combustion at the beginning of a furnace operating cycle

prior to initiating ignition.

Recycles

–

The additional attempts within the same thermostat

cycle for ignition after loss of the supervised ignition source

or the supervised main burner flame.

Retries

– The additional attempts within the same thermostat

cycle for ignition when the supervised main burner flame is

not proven within the first trial for ignition period.

Trial for Ignition Period (TFI)

–

The period of time between

initiation of gas flow and the action to shut off the gas flow in

the event of failure to establish proof of the supervised ignition

source or the supervised main burner flame.

DEFINITION OF TERMS

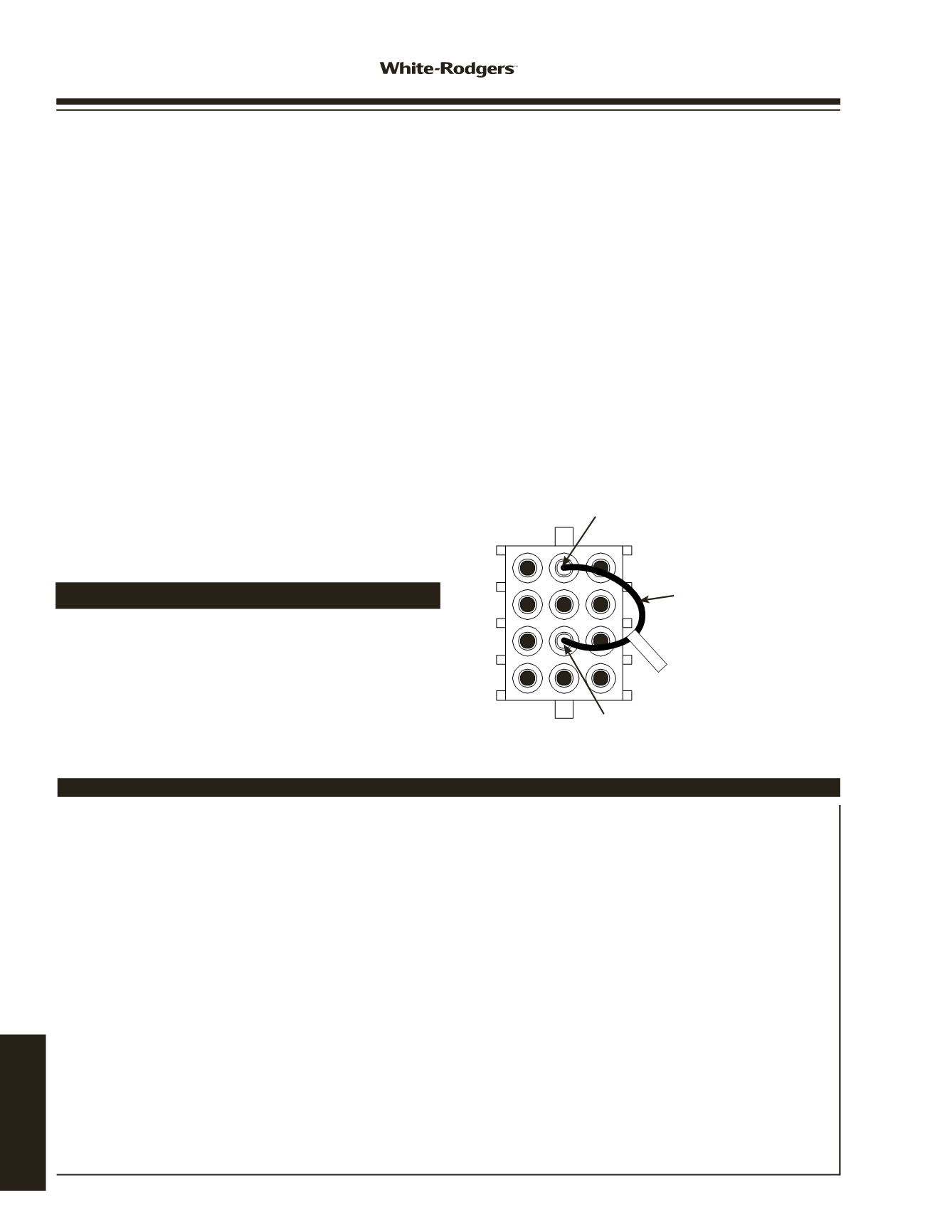

IMPORTANT:

For continuous fan speed operation, one of the un-

used parked motor taps must be connected to the low heat speed

terminal. Failure to do this will result in the blower not energizing in

the constant fan mode operation. Refer to figure 1.

For all Trane and AMERICAN STANDARD applica-

tions only:

Install jumper 0151 290600 (included in this pack-

age) in the furnace 12 pin connector harness, pin 5 and pin 11

positions. Make sure jumper snaps into the connector securely.

Refer to figure 1.

INSTALLER MUST READ FOR PROPER INSTALLATION

290600

J

Pin 11 (R10 In)

Pin 5 (R10 Out)

Jumper 0151-290600

(for Trane and American

Standard Applications only)

www.white-rodgers.com192

TECHNICAL HELP