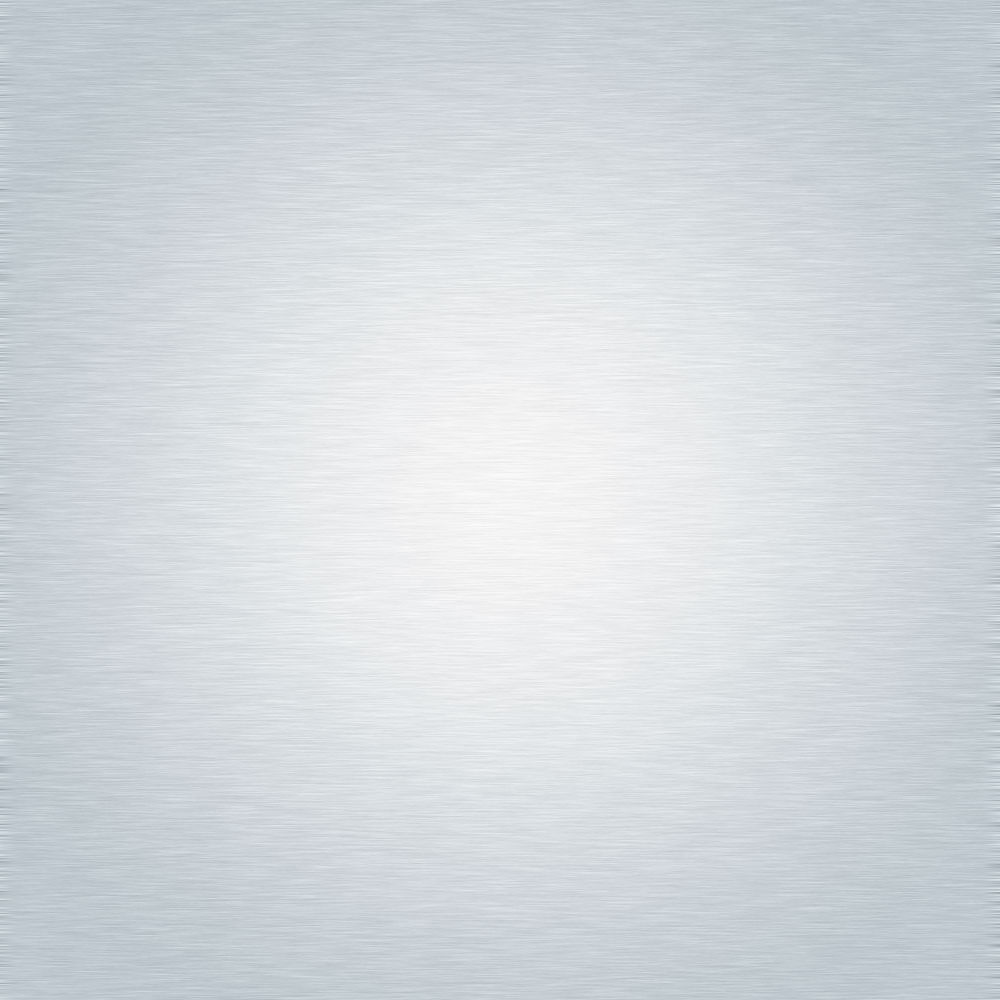

TYPICAL WIRING

1F95-1277

TYPICAL WIRING DIAGRAMS

System

O

RH

+

B

CLASS II

TRANSFORMER

HOT

24VAC

NEUTRAL

120VAC

W/E

G

C

-

W2

No

Output

24 VAC

(Hot)

Cool

Power

remote

Temp-

erature

Sensor

Remote

Temp-

erature

Sensor

signal

Power

Remote

Temp-

erature

Sensor

Y2 Y

RC

S

6

L

{

To Remote Temperature Sensor

24 VAC

(Hot)

Heat

24 VAC

Com-

mon

(option-

al) *

CLASS II

TRANSFORMER

120VAC

HOT

24VAC

NEUTRAL

HEATING

COOLING

Ener-

gized

in Heat

Mode

Energiz-

ed in

Cool &

Off

Mode

Cool

mode

2nd

Stage

(Com-

pressor)

Cool

Mode

1st

Stage

(Com-

pressor)

Blower/

Circula-

tor Fan

Energiz-

ed on

call for

Cool &

for Heat

(if ELE

is sel-

ected)

Heat

Mode

2nd

Stage

No

Output

Heat

Mode

1st

Stage

Ener-

gized

on call

for

Heat

Power

Closed

Conn-

ection

for

3-wire

zone

valve

Fault

Indicator

or

System

Malfunc-

tion

Switch

Single

Stage1

(SS1)

Multi-

Stage2

(MS2)

Comfort

Alert II module

or similar

malfunction

module

Single

Stage1

(SS1)

Multi-

Stage2

(MS2)

Energiz-

ed in

Cool &

Off

Mode

Ener-

gized

in Heat

Mode

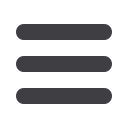

System

O

RH

+

B

CLASS II

TRANSFORMER

HOT

24VAC

NEUTRAL

120VAC

W/E

G

C

-

W2

Jumper

No

Output Cool

Mode

1st

Stage

(Com-

pressor)

Blower/

Circula-

tor Fan

Energiz-

ed on

call for

Cool &

for Heat

(if ELE

is sel-

ected)

24 VAC

(Hot)

Cool

Power

remote

Temp-

erature

Sensor

Remote

Temp-

erature

Sensor

signal

Power

Remote

Temp-

erature

Sensor

Heat

Mode

1st

Stage

Power

Closed

Conn-

ection

for

3-wire

zone

valve

Fault

Indicator

or

System

Malfunc-

tion

Switch

Y2 Y

RC

S

6

L

{

To Remote Temperature Sensor

Cool

mode

2nd

Stage

(Com-

pressor)

24 VAC

(Hot)

Heat

24 VAC

Com-

mon

(option-

al) *

Heat

Mode

2nd

Stage

No

Output

Ener-

gized

on call

for

Heat

Comfort

Alert II module

or similar

malfunction

module

Heat

Pump1

(HP1)

Heat

Pump2

(HP2)

Energiz-

ed in

Cool

& Off

Mode

Energiz-

ed in

Heat/

Emer-

gency

Mode

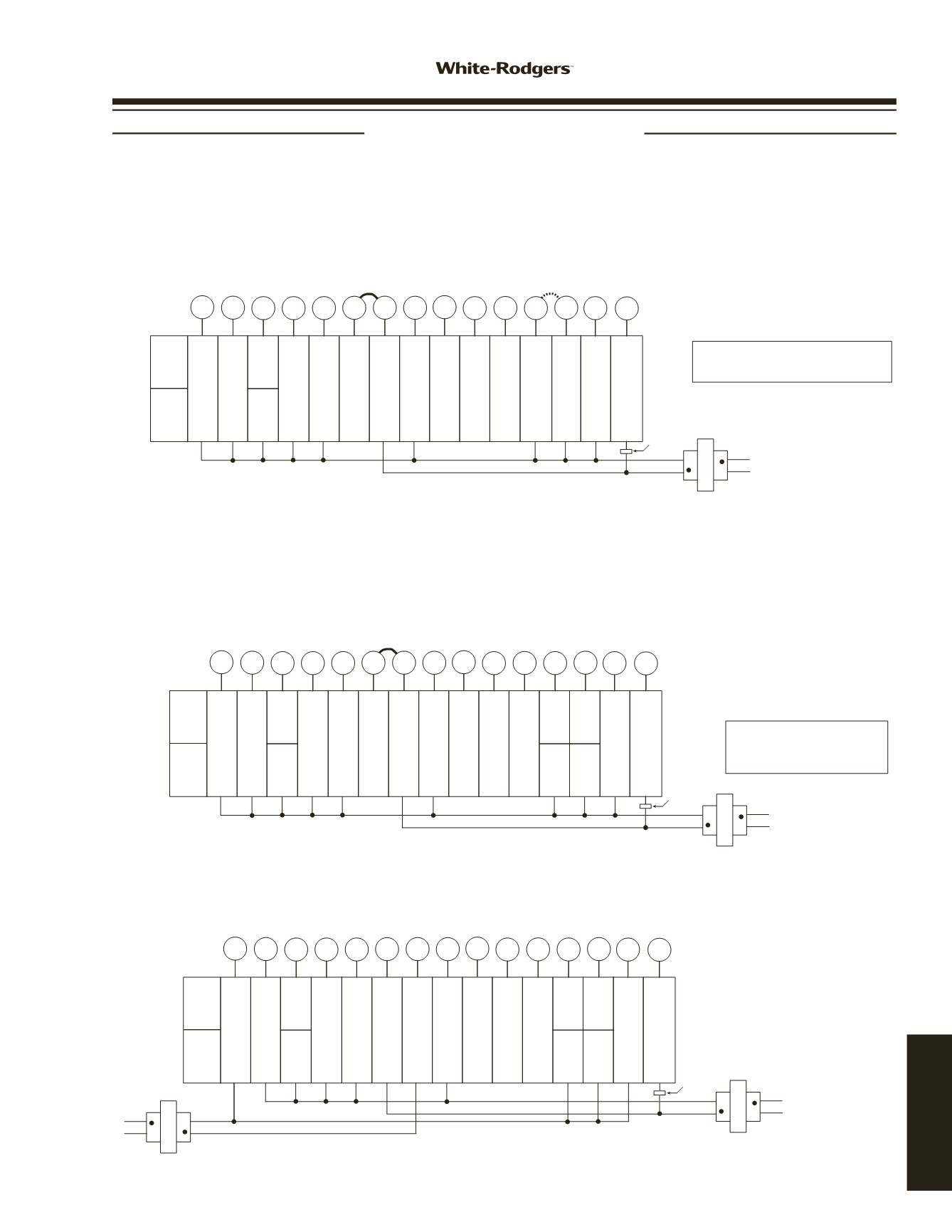

System

O

RH

+

B

CLASS II

TRANSFORMER

HOT

24VAC

NEUTRAL

120VAC

W/E

Jumper

G

C

-

W2

Jumper

No

Output 1st

Stage

Heat &

Cool

(Com-

pressor)

**

Blower/

Circula-

tor Fan

Energiz-

ed on

call for

Heat or

Cool

24 VAC

(Hot)

Cool

Power

remote

Temp-

erature

Sensor

Remote

Temp-

erature

Sensor

signal

Power

Remote

Temp-

erature

Sensor

Auxil-

iary &

Emer-

gency

Heat

1st

Stage

Power

Closed

Conn-

ection

for

3-wire

zone

valve

Fault

Indicator

or

System

Malfunc-

tion

Switch

Y2 Y

RC

S

6

L

{

To Remote Temperature Sensor

2nd

Stage

Heat/

Cool

(Com-

pressor)

24 VAC

(Hot)

Heat

24 VAC

Com-

mon

(option-

al) *

(Dual

Fuel

disabled)

Emer-

gency

heat

2nd stage

(Dual

Fuel

enabled)

Auxiliary

& Emer-

gency

heat

2nd stage

Comfort

Alert II module

or similar

malfunction

module

Heat Pump Connections

If you do not have a heat pump system, refer to figures 2 & 3.

Refer to equipment manufacturers' instructions for specific system

wiring information.

You can configure the thermostat for use with the following heat

pump systems.

HEAT PUMP TYPE 1 (HP 1)

. Single stage compressor system; gas

or electric backup.

HEAT PUMP TYPE 2 (HP 2)

. Multi-stage compressor or two com-

pressor system with gas or electric backup.

After wiring, see INSTALLER CONFIGURATION section for proper

thermostat configuration.

NOTE: If your system does not

provide an E connection, jumper W2

to W/E to use the Auxiliary Heat in the

Emergency Mode.

* 24 VAC common connection

optional for system operation.

Required for fault or malfunction indi-

cation, remote temperature sensor, or

for continuous backlight operation.

** Dual fuel option de-energizes

compressor when auxiliary heat is

energized.

Heat Pump Systems

Single Stage and Multi-Stage Connections

Refer to equipment manufacturers' instructions for specific system

wiring information.

This thermostat is designed to operate a single-transformer or two-

transformer system.

You can configure the thermostat for use with the following fossil fuel

systems:

Single stage (SS 1)

gas, oil or electric.

Multi-stage (MS 2)

gas, oil or electric.

After wiring, see INSTALLER CONFIGURATION section for proper

thermostat configuration.

Single Stage or Multi-Stage System (No Heat Pump) with Single Transformer

Single Stage or Multi-Stage System (No Heat Pump) with Two Transformers

* 24 VAC common connection

optional for system operation.

Required for fault or malfunc-

tion indication, remote temper-

ature sensor, or for continuous

backlight operation.

NOTE

: If continuous backlight or hardwired

power input are desired but do not function

in both HEAT and COOL modes, cut the

heating transformer 24V wires and tape off.

Connect the neutral circuit disconnected

from the heating transformer to the neutral

circuit of the cooling transformer. Discon-

nect the wire to the RH terminal and install

a jumper between RH and RC. Depending

on the system requirements, replace the

cooling transformer with a 75VA class II

transformer if needed.

www.white-rodgers.com137

TECHNICAL HELP