96-TS SUCTION LINE DRIERS

Driers Designed to Clean Up Your Refrigerant System After a

Compressor Burnout has Occurred. Removes Solid Contaminants

and Harmful Acids that are Created During a Motor Burnout. Another

Application: The 96-TS Installed as a Suction Line Filter-Drier in

Remote Systems with Long Refrigerant Lines. The Filter-Drier will

Collect and Hold Any Dirt that is in the Evaporator or Suction Line

at Start-Up

FEATURES

• Dual access valve on each end of the drier for accurate pressure drop readings

across the drier.

• Solid block desiccant core effectively removes and holds a maximum amount of

contaminants with minimal pressure drop.

• Provides high moisture, organic and inorganic acid removal.

• Binding material within the core protects the core from acid decomposition and

allows the core to collect and hold the acids from a motor burnout.

• Inlet deflector spreads the refrigerant flow evenly across the molded core to

provide full filtration capacity and to prevent erosion of the core.

• For use with HCFCs, CFCs and the lubricants that go with them.

• Nickel plated SAE flare and solid copper ODF fittings.

• Corrosion resistant paint.

SPECIFICATIONS

Maximum Working Pressure . . . . . 500 psig

Minimum Burst Pressure . . . . . . . 2500 psig

Agency . . . . . . . . . . . . . . . . . . . . . . . . . . . UL/CUL file number SA11002

INSTALLATION NOTE

: The 96-TS suction line filter-drier may be installed in any position in the

suction line as close to the compressor as possible, ahead of the accumulator if there is one in

the system.

In low temperature applications, the drier should be installed in a vertical position with the flow in

a downward direction to prevent oil accumulation.

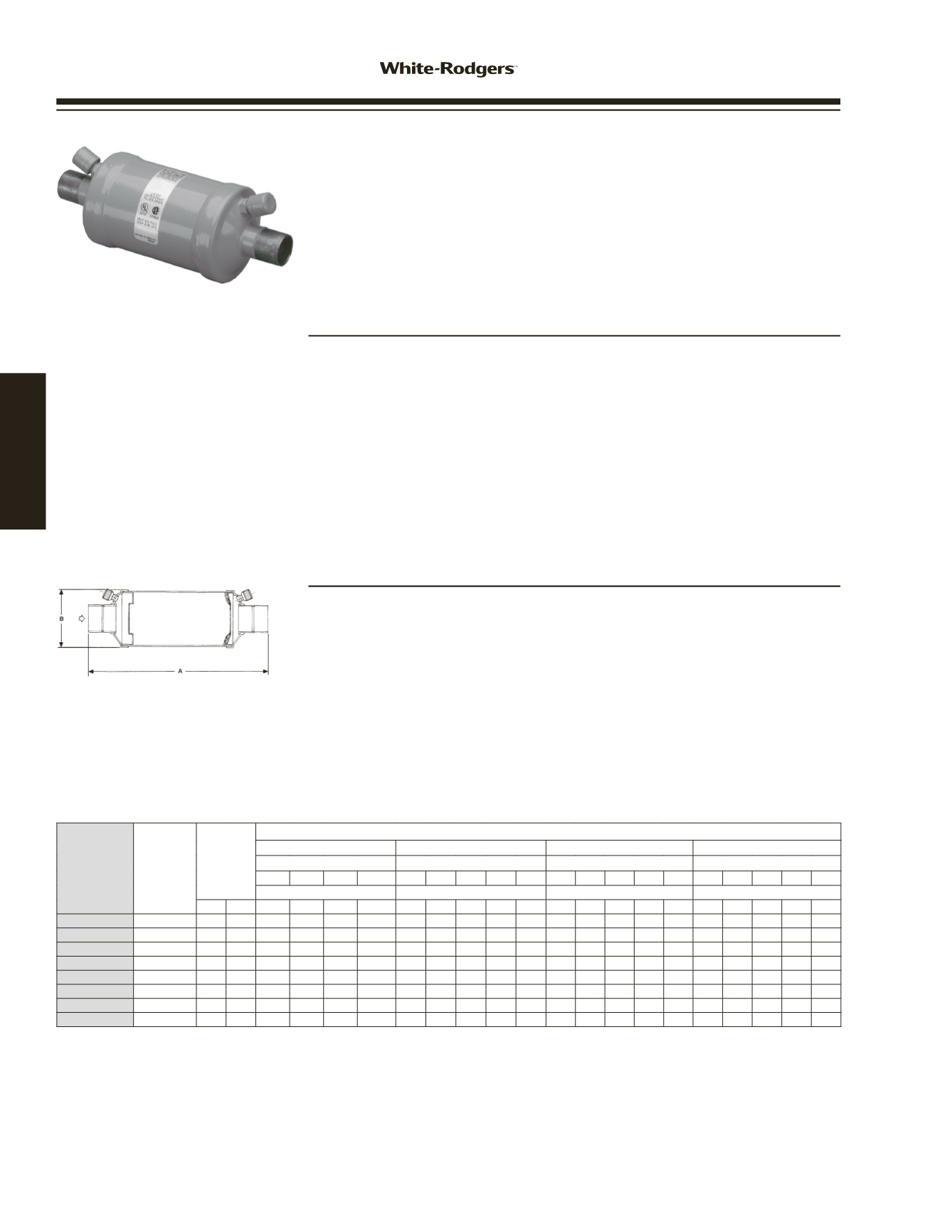

SELECTION NOTE

: Given the proper suction line size, connection type and tonnage of the

refrigerant system, the correct drier may be selected using the chart below.

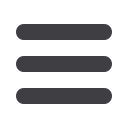

96-TS

96-TS Series

Dimensional Drawing

SELECTION:

Connections, Dimensions, Flow Capacities

➀

in refrigerant tons at selected evaporator temperatures

Model Number Connection

Dimension

Flow Capacity in Tons Refrigerant

1

(For kW, Multiply Tons By 3.5)

2

R-134a

R-22

R-410A

R502

Evaporator Temperature (

o

F) Evaporator Temperature (

o

F) Evaporator Temperature (

o

F) Evaporator Temperature (

o

F)

40 20 0 -20 40 20 0 -20 -40 40 20 0 -20 -40 40 20 0 -20 -40

Pressure Drop (PSI)

Pressure Drop (PSI)

Pressure Drop (PSI)

Pressure Drop (PSI)

A B 2 1.5 1 0.5 3 2 1.5 1 0.5 3 2 1.5 1 0.5 3 2 1.5 1 0.5

96-TS085S

5/8 ODF 5.74 2.5 2.4 1.6 1.0 0.5 3.8 2.5 1.7 1.1 0.6 3.9 2.6 1.7 1.1 0.6 2.5 1.6 1.1 0.7 0.4

96-TS164S

1/2 ODF 6.27 2.5 1.7 1.2 0.7 0.4 2.7 1.8 1.2 0.8 0.4 2.8 1.8 1.2 0.8 0.4 1.8 1.2 0.8 0.5 0.3

96-TS165S

5/8 ODF 6.54 2.5 2.2 1.5 0.9 0.5 3.4 2.2 1.5 1.0 0.5 3.5 2.2 1.5 1.0 0.5 2.2 1.4 1.0 0.6 0.3

96-TS166S

3/4 ODF 6.95 2.5 2.6 1.8 1.1 0.6 4.1 2.7 1.8 1.2 0.6 4.2 2.8 1.8 1.2 0.6 2.7 1.8 1.2 0.8 0.4

96-TS167S

7/8 ODF 7.13 2.5 2.6 1.8 1.1 0.6 4.1 2.7 1.8 1.2 0.6 4.2 2.8 1.8 1.2 0.6 2.7 1.8 1.2 0.8 0.4

96-TS306S

3/4 ODF 9.63 3.0 3.4 2.3 1.4 0.8 5.4 3.5 2.4 1.5 0.8 5.5 3.6 2.4 1.5 0.8 3.5 2.3 1.6 1.0 0.5

96-TS307S

7/8 ODF 9.80 3.0 3.8 2.5 1.6 0.8 5.9 3.9 2.6 1.7 0.9 6.0 4.0 2.6 1.7 0.9 3.8 2.5 1.7 1.1 0.6

96-TS309S

9/8 ODF 9.80 3.0 3.9 2.6 1.6 0.8 6.1 4.0 2.7 1.7 0.9 6.2 4.1 2.8 1.7 0.9 4.0 2.6 1.8 1.1 0.6

1

All Ratings in accordance with ARI standard 700-04

2

Example: 1.0 tons x 3.5 = 3.5 KW

96-TS

SERIES

SUCTION LINE

FILTER-DRIERS

www.white-rodgers.com90

COOLING /

REFRIGERATION