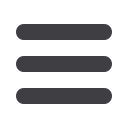

36G, 36J SERIES

GAS VALVES

GAS BURNER

CONTROLS

PARTS AND ACCESSORIES

See end of this section for parts and accessories

TECHNICAL HELP

Wiring Diagrams . . . . . . . . . . . See page 178

?

36J Series

page

178

36G, 36J SERIES GAS VALVES

The 36G, 36J is a Combination Gas Control Valve Designed for

Use with Non-Piloted Intermittent Ignition Systems. The Control

is Designed to Meet Today’s Maximum Capacity, Smaller Size

and High Efficiency Gas Systems

FEATURES

• Inlet and outlet screens.

• Quiet redundant.

• Built-in pressure tap.

• Quick-connect terminals (

1

/

4

”

).

SPECIFICATIONS

Ambient Temperature . . . . . . . . -40 to 175°F

Maximum Pressure Rating . . . . . .

1

/

2

”

PSI (14.0

”

W.C.)

Capacity (1

”

P.D.) . . . . . . . . . Natural 140,000 Btu/Hr.

L.P. 226,800 Btu/Hr.

Electrical Rating . . . . . . . . . . . . . . . . . . . . Single stage 24V, 50 / 60Hz at .3A

Two stage at .43A

Swing Radius . . . . . . . . . . . . . . . . . . . . . . 2.75

”

Mounting . . . . . . . . . . . . . Any position

Agency . . . . . . . . . . . . . . . . . . . . . . . . . . . C.S.A. approved

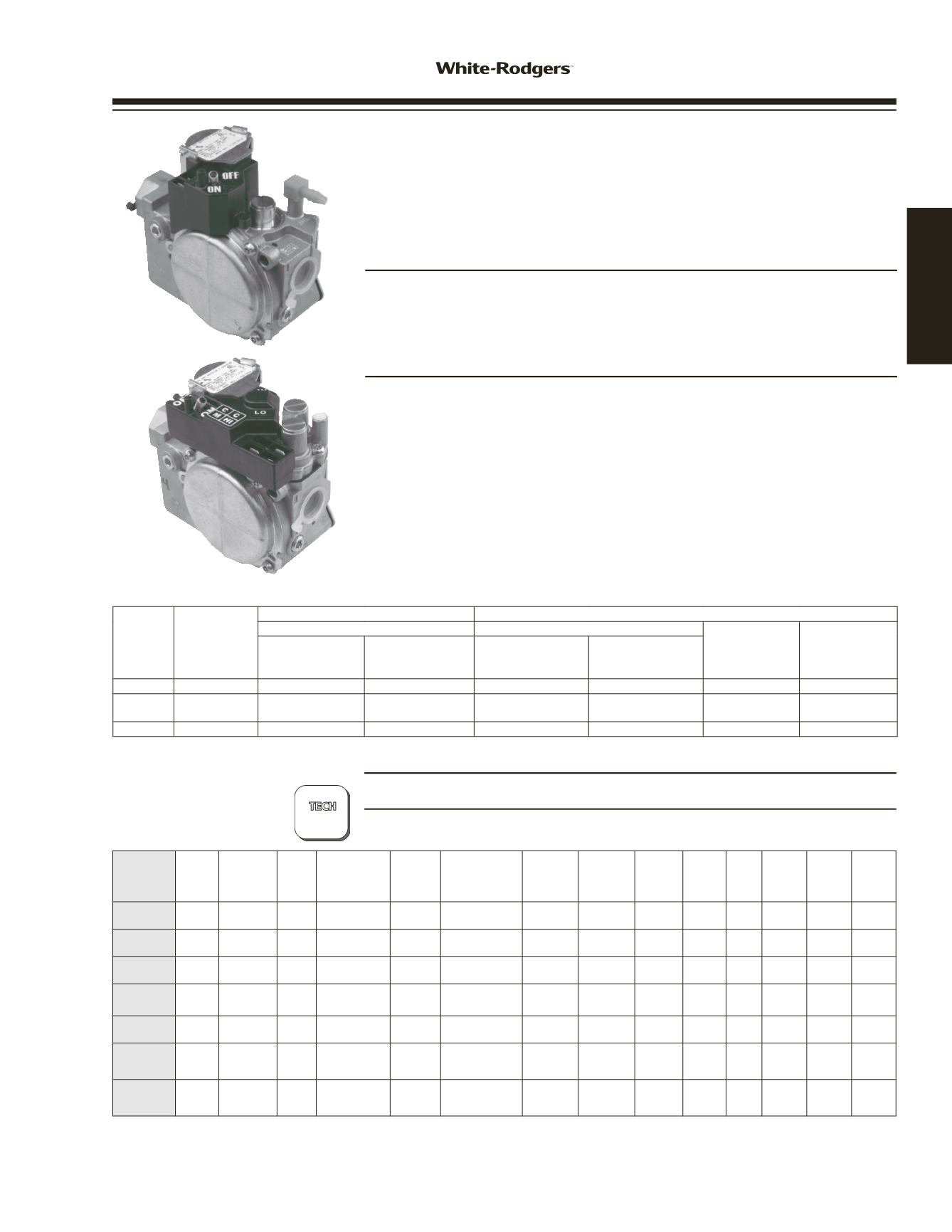

Valve

(Stages)

Pipe Size

1

”

Pressure Drop Capacity

Range of Regulation

BTU/HR

BTU/HR

Adjustment

Range

(Nat. IN. W.C.)

Adjustment

Range

(L.P. IN. W.C.)

Std. Gas

.64 Sp. Gr.

(1000 BTU/CU. FT.)

LP Gas

1.53 Sp. Gr.

(2500 BTU/FT.)

Std Gas

.64 Sp. Gr.

(1000 BTU/CU. FT.)

LP Gas

1.53 Sp. Gr.

(2500 BTU/FT.)

Single 1/2

”

x 1/2

”

NPT 140,000 BTU/HR 226,800 BTU/HR 40,000-210,000

60,000-340,000

2.5

”

-5.0

”

7.0

”

-12.0

”

Two 1/2

”

x 1/2

”

NPT 140,000 BTU/HR 226,800 BTU/HR

20,000 Low-

210,000 High

32,000 Low-

340,000 High

1.0

”

-4.0

”

Low

2.0

”

-5.0

”

High

4.0

”

-10.0

”

Low

6.0

”

-12.0

”

High

Modulating 1/2

”

x 1/2

”

NPT 140,000 BTU/HR 226,800 BTU/HR 20,000 - 210,000

32,600 - 340,000

0.40

”

-4.0

”

1.3

”

-11.5

”

Model

Number

Coil

Voltage Gas Type

Pipe

Size

Opening

Characteristic

Regulator

Setting

Regulator

Adjustment

Range

Convertible

Nat. / LP

LP

Conversion

Kit

Included

Flow

Direction

Reducer

Bushing

Kit

Filter

Screen

Inlet

Pressure

Tap

Outlet

Pressure

Tap

Internal

Wiring

See

Figure

➀

36G22-254

24 VAC Natural or

LP

1

/

2

x

1

/

2

Fast Opening

Single Stage

3.5

”

Nat. 2.5

”

- 5.0

”

L.P. 7.0

”

- 12.0

”

Yes

No** Str. Thru No Yes Yes Yes*

1

36J22-214

24 VAC Natural or

LP

1

/

2

x

1

/

2

Fast Opening

Single Stage

3.5

”

Nat. 2.5

”

- 5.0

”

L.P. 7.0

”

- 12.0

”

Yes

Yes Str. Thru Yes Yes Yes Yes

1

36J24-214

24 VAC Natural or

LP

1

/

2

x

1

/

2

Slow Opening

Single Stage

3.5

”

Nat. 2.5

”

- 5.0

”

L.P. 7.0

”

- 12.0

”

Yes

Yes Str. Thru Yes Yes Yes Yes

1

36J54-214

24 VAC Natural or

LP

1

/

2

x

1

/

2

Two-Stage

Fast Opening

LO 1.5

”

HI 3.5”

Nat. 2.5

”

- 5.0

”

L.P. 6.0

”

- 12.0

”

Yes

Yes Str. Thru Yes Yes Yes Yes*

2

36J55-214

24 VAC Natural or

LP

1

/

2

x

1

/

2

Two-Stage

Slow Opening

3.5

”

Nat. 2.5

”

- 5.0

”

L.P. 6.0

”

- 12.0

”

Yes

Yes Str. Thru Yes Yes Yes Yes*

2

36J24-614

24 VAC Natural or

LP

1

/

2

x

1

/

2

Single Stage

Slow Opening

3.5

”

Nat. 2.5

”

- 5.0

”

L.P. 7.0

”

- 12.0

”

Yes

Yes

90

o

Bottom

Outlet

No Yes Yes Yes*

2

36J55-614

24 VAC Natural or

LP

1

/

2

x

1

/

2

Two-Stage

Slow Opening

3.5

”

Nat. 2.5

”

- 5.0

”

L.P. 6.0

”

- 12.0

”

Yes

Yes

90

o

Bottom

Outlet

No Yes Yes Yes*

2

* To measure outlet pressure on valves, loosen outlet pressure tap screw one quarter turn and put manometer hose over the top of the outlet pressure tap.

** Use F92-0659 to convert to regulated L.P. gas

➀

Wiring diagrams – see page 178

www.white-rodgers.com41

HEATING