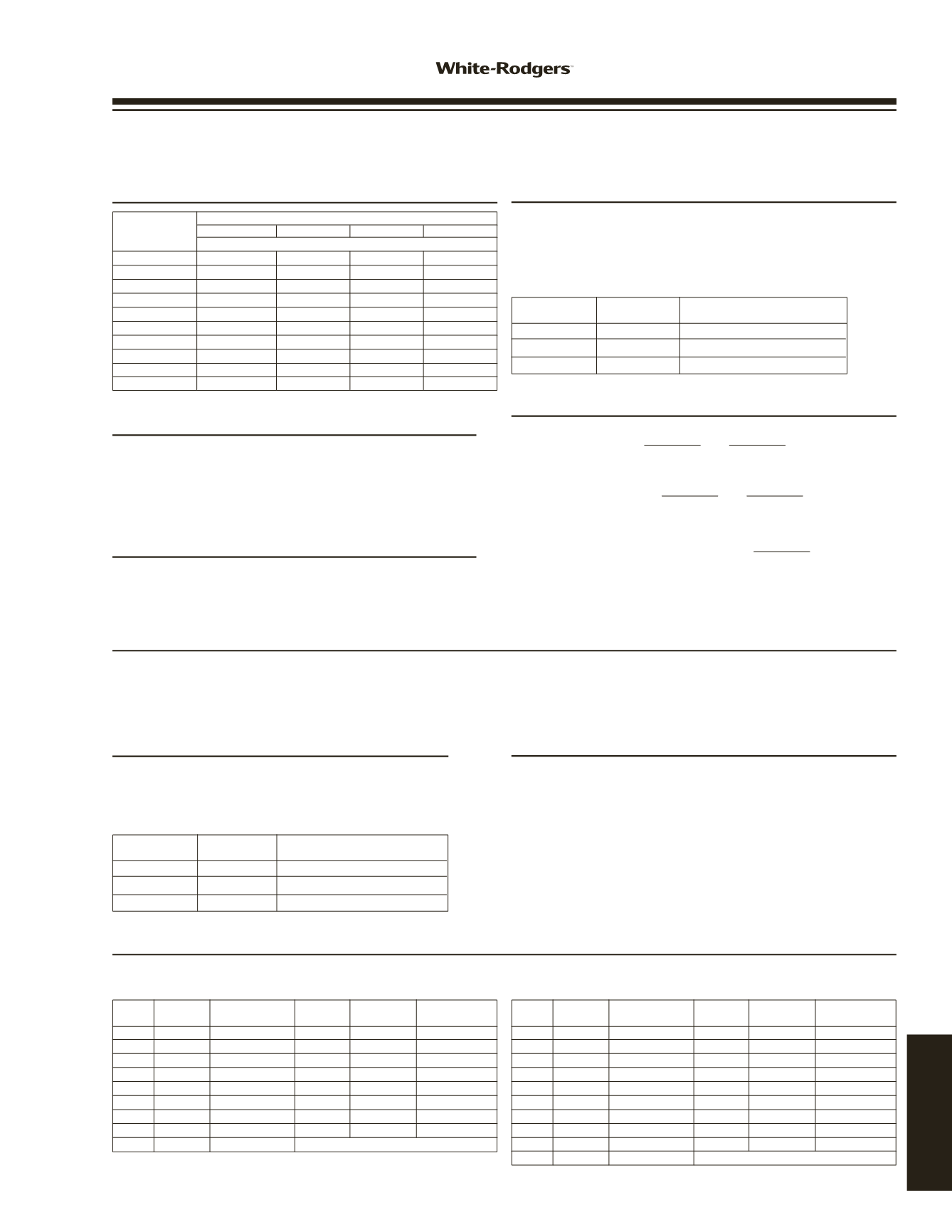

GENERAL

INFORMATION

www.white-rodgers.com221

TECHNICAL HELP

GAS

Drill Diameter Natural Gas Drill

Diameter Natural Gas

Size (inches)

(Btu/Hr)

Size

(inches)

(Btu/Hr)

56 .0465

5,359

26

.1470

53,500

54 .0550

7,510

22

.1570

61,100

52 .0635

10,000

18

.1695

71,200

46 .0810

16,250

12

.1890

88,600

42 .0935

21,680

6

.2040

103,200

38 .1015

25,530

2

.2210

121,100

34

.1110

30,550

A

.2340

135,700

31 .1200

35,690

E(

1

/

4

)

.2500

154,900

30 .1285

40,900

Drill Diameter

LP Gas

Drill

Diameter

LP Gas

Size (inches)

(Btu/Hr)

Size

(inches)

(Btu/Hr)

70 .0280

5,490

46

.0810

45,800

67 .0320

7,150

44

.0860

51,600

64 .0360

9,050

42

.0935

61,100

61 .0390

10,600

38

.1015

72,000

58 .0420

12,300

34

.1110

86,200

56 .0465

15,100

30

.1285

115,300

54 .0550

21,200

26

.1470

151,000

52 .0635

28,200

22

.1570

172,000

50 .0700

34,200

18

.1695

200,500

48 .0760

40,400

Table for

Natural Gas

at 3.5

”

W.C. with 1000 Btu/Cu. Ft.,

.65 Specific Gravity and .82 orifice coefficient.

Table for

Propane (lp) Gas

at 11.0

”

W.C. with 2500 Btu/Cu. Ft.,

1.53 Specific Gravity and .80 orifice coefficient.

RATE OF FLOW OF GASES THROUGH ORIFICES

Total Heating Specific

Conversion Factor

Value (Btu/Cu.

Gravity

(multiply listed capacity by:)

Less than 800

0.60

0.516

800 to 950

0.70

0.765

2500 (LP Gas)

1.53

1.620

Capacities shown in this catalog are for AGA Standard Gas

(1000 Btu/Cu. Ft., .64 Specific Gravity) at 1.0”W.C. pressure

drop across valve. Table below shows conversion factors for

other gases.

CONVERSION FACTORS

FOR GAS VALVE CAPACITIES

BTU CONTENT OF FUELS

Natural Gas.................950 to 1,150 Btu/Cu. Ft.

Butane Gas.................3,200 Btu/Cu. Ft.

Propane (LP) Gas.......2,500 Btu/Cu. Ft.

No. 2 Oil......................140,000 Btu/Gallon

ELECTRIC

Voltage (AC – Single Phase)

120

208

240

277

Watts

Amperes

500

4.2

2.4

2.1

1.8

1000

8.3

4.8

4.2

3.6

1500

12.5

7.2

6.3

5.4

2000

16.7

9.6

8.3

7.2

2500

20.9

12.0

10.4

9.0

3000

25.0

14.4

12.5

10.8

3500

29.2

16.8

14.6

12.6

4000

33.3

19.2

16.7

14.4

4500

37.5

21.6

18.8

16.3

5000

41.7

24.0

20.8

18.0

CONVERSION TABLE FOR

WATTS – AMPERES – VOLTS

heat and power equivalents

1 Btu............................252 calories

1 Btu/Hr.......................0.293 watts

1 Watt..........................3.413 Btu/Hr

1 Kw (1000 Watts).......3413 Btu/Hr

1 Hp............................0.746 Kw

PRESSURE CONVERSION TABLE

1

”

Water......................0.0361 lbs/sq. in. or 0.0735 in. Mercury

1

”

Mercury..................13.6 in. water or 0.491 lbs/sq. in.

1 PSI...........................27.7 in. water or 2.036 in. Mercury

Wire

Max. Length Maximum Combined Length

Sizes

(2-Wire Cable)

(2 Single Wires)

No. 18

30 ft.

60 ft.

No. 16

50 ft.

100 ft.

No. 14

80 ft.

160 ft.

Because of the small amount of power available on self-

generating systems, the gas valve may not operate if there

is too much resistance in the circuit. Therefore, choose a

location that does not require any more wire than the recom-

mended lengths shown in the table below.

MAXIMUM WIRE LENGTHS

FOR SELF-GENERATION SYSTEMS

P (Watts)

E (Volts)

I (Amps) =

=

E (Volts)

R (Ohms)

VARIATIONS OF OHMS LAW

E (Volts)

I (Amps)

R (Resistance) =

=

P (Watts)

I2 (Amps)

E (Volts) = I (Amps) x R (Ohms) =

P (Watts)

I (Amps)

P (Watts) = I2 (Amps) x R (Ohms) = I (Amps) x E (Volts)

ELECTRIC AND GAS