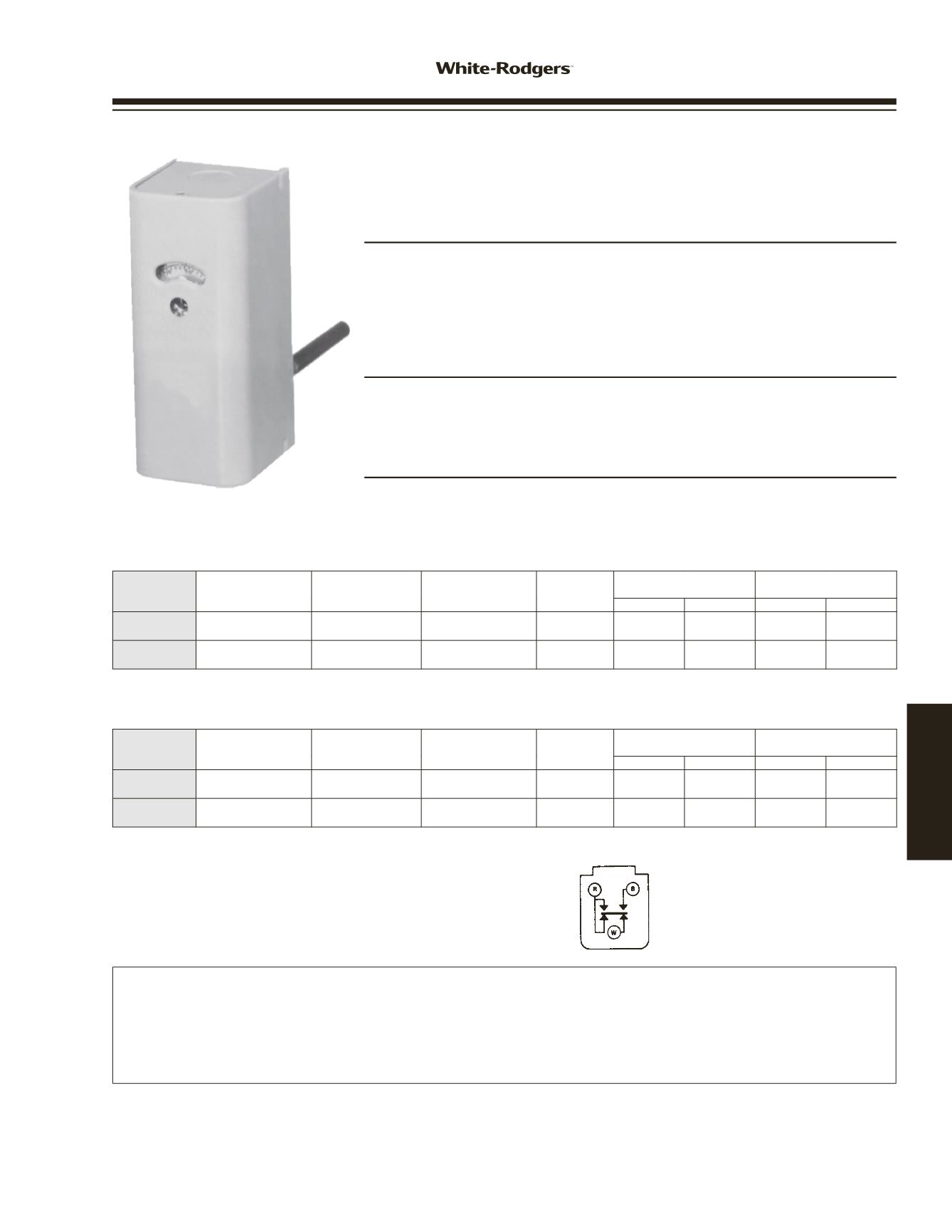

WELL IMMERSION

CONTROLS

HYDRONIC

CONTROLS

11D18-1

SPDT Contact Structure

HH Rated Controls

Switch Action

R-B Open on Rise

R-W Close on Rise

CONTRACTOR TIP:

TESTING AUTOMATIC TEMPERATURE CONTROLS

To verify a control is opening and closing properly,

disconnect all power before testing. Testing must be performed with the sensing element at a temperature within the setting range of the

control. For most hydronic controls with a range of 100 to 240°F, a pan of hot water is sufficient to reach the control range.

Attach an ohmmeter or continuity tester across the Open on Rise contacts. Lower the temperature setting dial to the lowest setting.

If the lowest setting is below the temperature of the sensing element minus the differential of the control, the contacts should be open.

Raise the temperature dial slowly. When the setting is raised above the temperature of the sensor, the contacts should close.

TYPES WITH BULBS DIRECTLY INTERCHANGEABLE WITH HONEYWELL

(3

9

/

16

” x

3

/

8

”

)

No wells included.

Model

Number

Range

Differential

Switch

Action

Full

Electrical

Rating

Motor Rating

(Full Load)

Valves and

Relays

120 VAC 240 VAC

24 VAC 0.3-12v DC

11D18-1

➀

100 to 240°F

(38 to 116°C)

5 to 45°F

(3 to 25°C)

Open on Rise

HTV

See page 222

10.0A

6.0A

6.0A

1.0A

11D31-1

100 to 240°F

(38 to 116°C)

7 to 45°F

(4 to 25°C)

SPDT

HH

See page 222

7.4A

3.7A

2.9A

—

➀

Has U.L. approved adjustable dial stop, factory set at 150°F maximum.

TYPES WITH TAPERED BULBS

(2

7

/

16

” x

7

/

16

”

)

All types include

1

/

2

”

standard shank well, unless otherwise specified.

Model

Number

Range

Differential

Switch

Action

Full

Electrical

Rating

Motor Rating

(Full Load)

Valves and

Relays

120 VAC 240 VAC

24 VAC 0.3-12v DC

1131-102

➀

100 to 240°F

(38 to 116°C)

7 to 45°F

(4 to 25°C)

SPDT

HH

See page 222

7.4A

3.7A

2.9A

—

11B18-101

➀

100 to 240°F

(38 to 116°C)

5 to 45°F

(3 to 25°C)

Open on Rise

HTV

See page 222

10.0A

6.0A

6.0A

1.0A

➀

Has U.L. approved adjustable dial stop, factory set at 150°F maximum.

WELL IMMERSION SINGLE CONTROL

Types for Use as High Limit, Reverse Action or SPDT Switching

Action: May be Mounted Either Horizontal or Vertical

FEATURES

• Extra capillary length for extended shank wells.

• Special screw terminals with “ears” securely hold solid and stranded wires.

• Screwdriver-adjustable differential with direct-read indicator.

• Knockouts on top and bottom and plenty of wiring room.

• Hydraulic action element – fast acting.

SPECIFICATIONS

Dimensions . . . . . . . . . . . . 5

3

/

8

”

H + 2

5

/

16

”

coil x 2

9

/

16

”

D

Finish . . . . . . . . . . . . . . Grey

Agency . . . . . . . . . . . . . . . . . . . . . . . . . . . U.L. listed and C.S.A. approved

PARTS AND ACCESSORIES

See end of this section for additional parts and accessories

• F145-0163 — Tube heat conductive compound

• Immersion wells — see page 108

www.white-rodgers.com107

HYDRONIC /

APPLIANCE